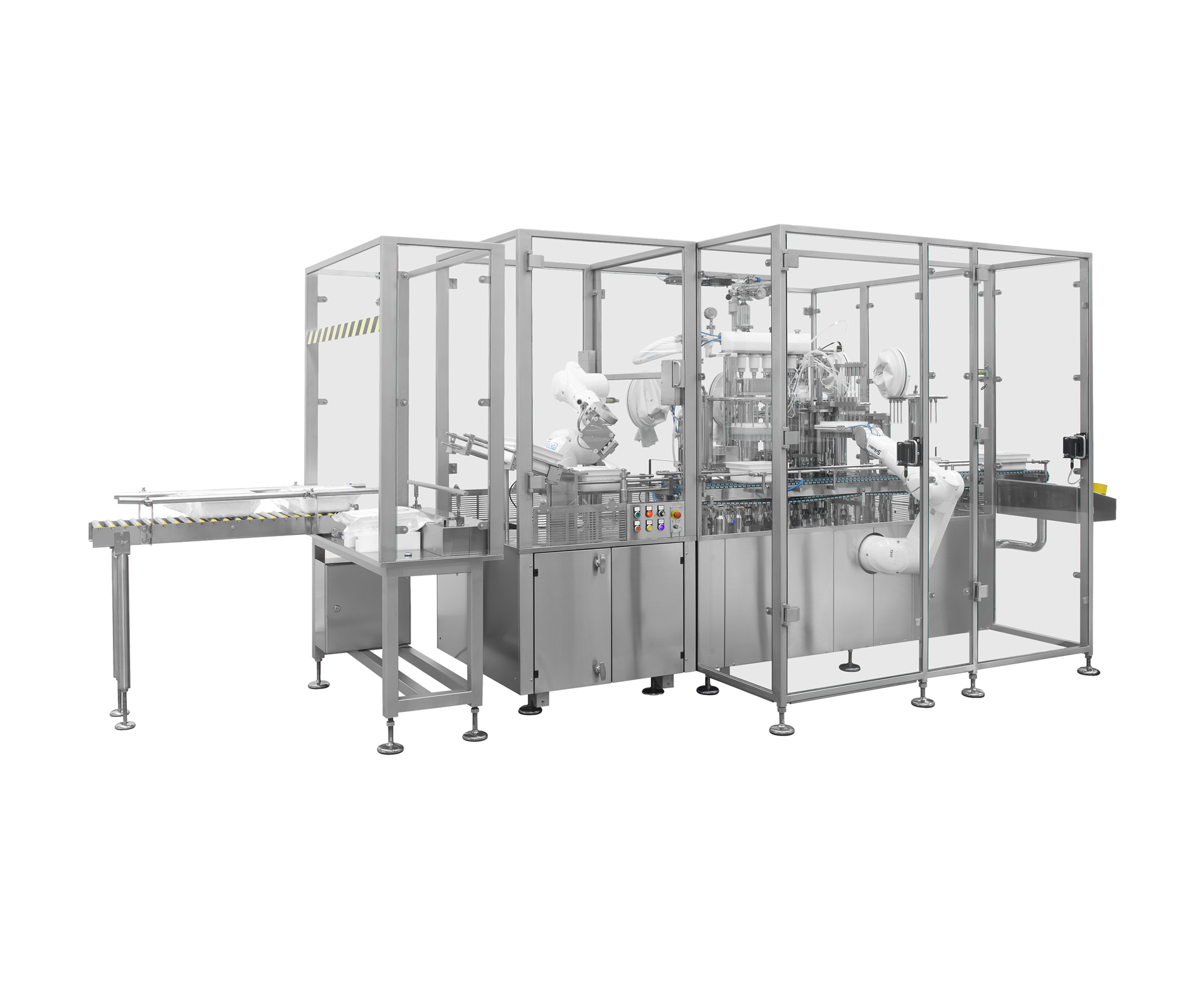

OUR ASEPTIC FILLING SYSTEMS

- Our Aseptic Filling Systems process vials, cartridges, syringes and ampoules

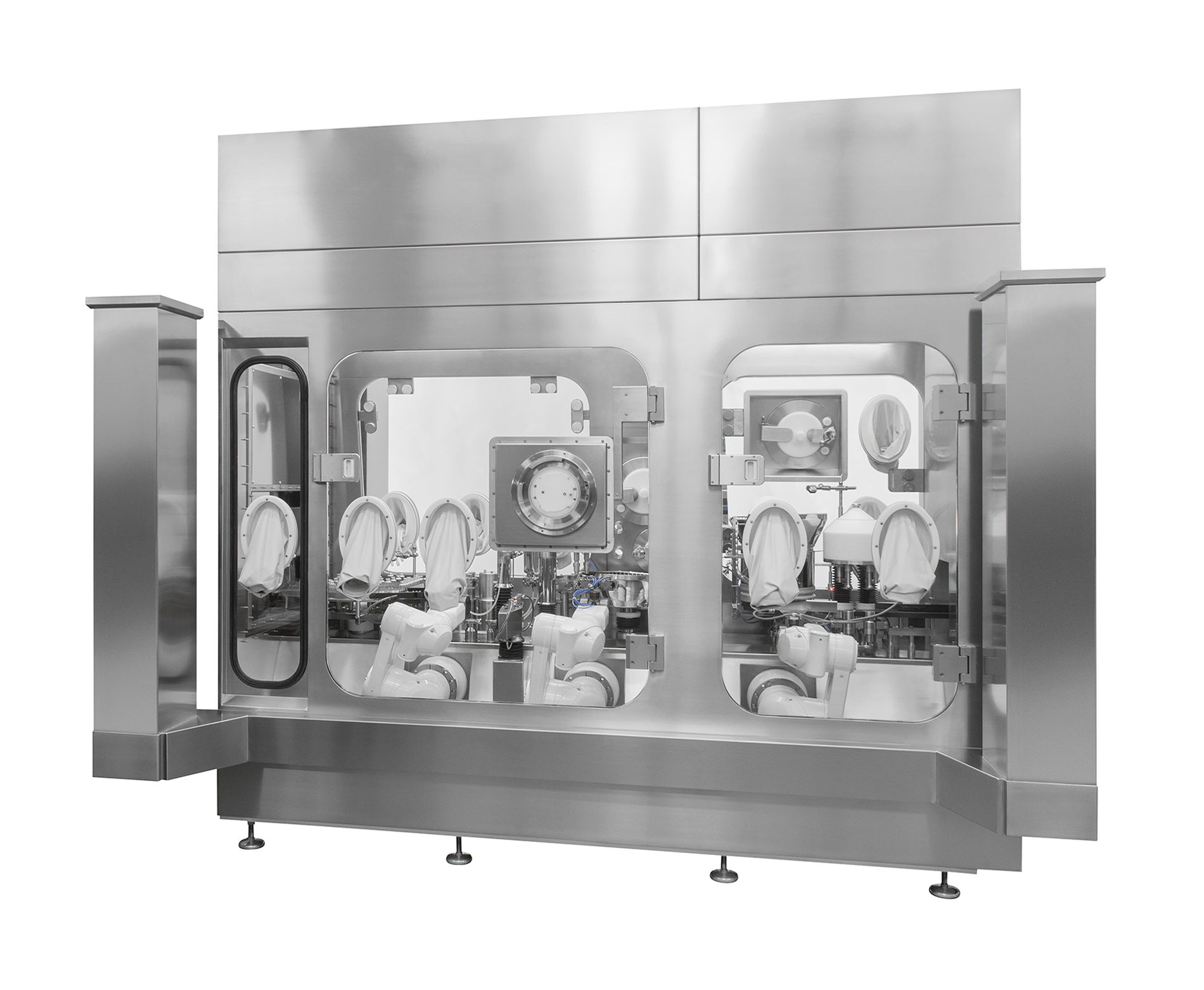

- Features In-line transport and small width, suitable for the application of RABS and isolators

- Volume to be monitored and sterilized is reduced

- Continuous monitoring of the viable and non-viable particles

- Moreover, servomotors actuate filling by volumetric pumps and/or peristaltic pumps

- Nitrogen purging inside the containers before, during and after the filling

- 100% IPC (In Process Control) of the weight and statistical Check Weighing system with feedback to the dosing pumps

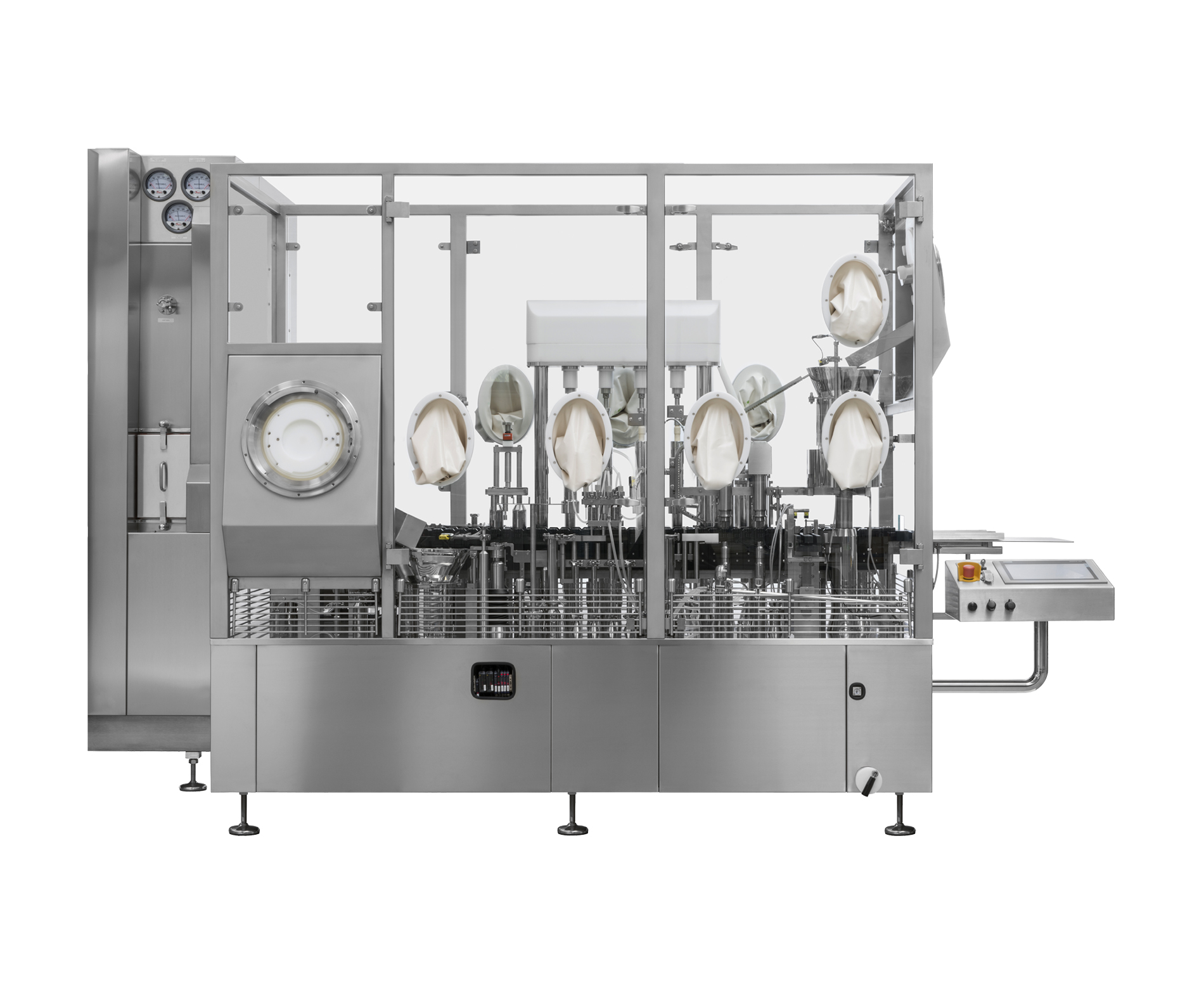

- Optional processing of pre-filled syringes (loaded from the nests)

- Vibration generator for the bowl of stoppers inside the mechanical volume, below the process area

- Designed to reduce particle generation by rotating the vials under the blades

- Further options include adding an ampoule closing station

- Lastly, all of our Aseptic Filling Systems are in compliance with cGMP, GAMP and 21CFR Part11 requirements

Additionally, please send us your preferred container size and run rate and we will provide a customized line quote per your specific requirements.